Underside.

I’ve had the good fortune to be given the loan of a rotisserie for the car, which will enable me to access the underside far easier than if it were on axle stands. I’m getting far too old to be laying under cars, so this is far more civilised. Luckily I had already replaced the front crossmember onto which the rotisserie attaches, or else there would have been insufficient strength to support the weight of the car. The engine, front subframe, interior and rear axle have been removed, but there’s still a fair weight to the shell. It can rotate 360 degrees if required, but my courage has only allowed it to turn to 90 degrees so far. With the car at this angle, you can see the new front crossmember and the ‘crow’s feet’ in the corners which are now welded to the wings. What you can also see is that there’s a large section of the O/S chassis rail missing. Unfortunately this was lost to rust and unfortunately it’s becoming a growing theme to the restoration. The new rails have been collected and can be seen on the floor in readiness for final fabrication and welding into place.

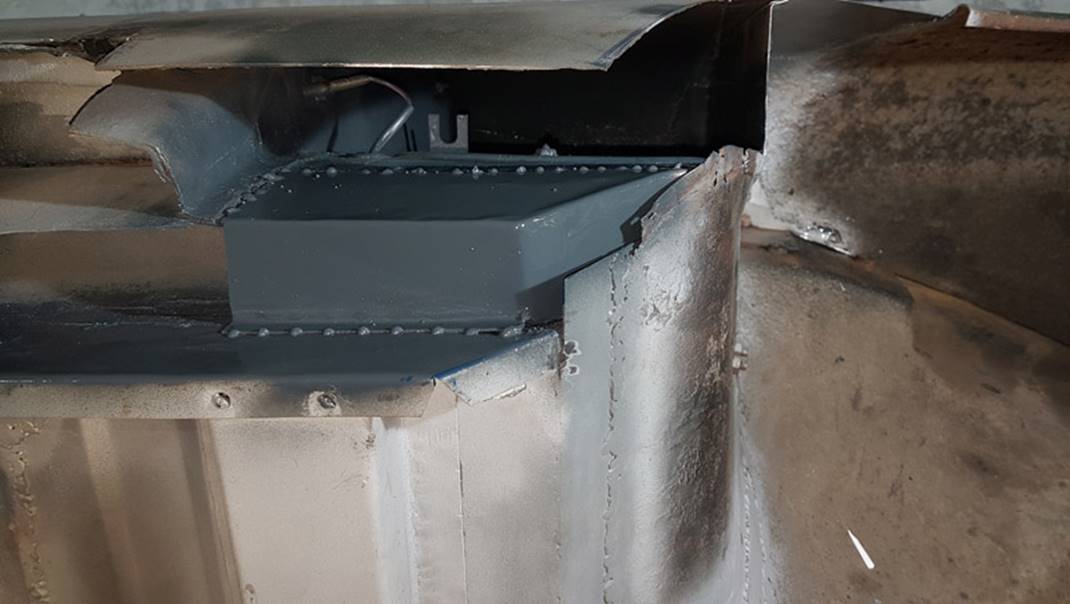

I’m happy enough now that the front end has been replaced, so I’ll be working my way back along the car. Initially I’ll be tackling the offside, with the nearside left untouched so I can use it as a reference if required. The car is renowned for rusting on all four jacking points, which inevitably results in the floor sections above them also rusting. Mine was no exception. As already mentioned, the chassis rail section in the same area as the O/S front jacking point was rotten. This was so bad that a replacement of the complete chassis rail was the only feasible option. Here’s the new floor section tacked into place. You can see the chassis rail on the right has almost completely gone in places. The inner sill was rotten too, and you can see I’ve started to replace it with homemade sections along the left hand side of the picture. At this point in the restoration, it feels as though I’ve swept up more of the car from the floor than what’s left!

The chassis rails are attached to the shell with spot welds to the floor which needed to be drilled out. The drilling wasn’t too much of a problem with the correct tool, but locating them in the first place was a little tricky. I missed a couple, but fortunately I was able to fatigue them off with no further damage to the floor. The holes from drilling out the spot welds will be used to plug weld the new chassis rails into place.

Once the old rail was off, the underside of the floor was cleaned up a little in preparation for the new one to be welded in.

Some beefy welding required for the chassis so the welder was turned up to 11. I ordered 2 sections of channelled 2mm steel to use as the new chassis rails, which is the same grade as used originally on the car. I needed to form a slight elbow at one end to follow the shape of the body and join onto the existing rail in the engine bay area. At the opposite end, a wide dart was required to locate into the rear suspension spring hanger. I cut the top off the rail, spread it to the correct shape and welded in a new top section of 2mm steel to complete the dart.

So, the rail O/S is in and welded up. There are just a couple of small sections of the floor to do to complete this area. I have also made and welded in the next section of the inner sill, fabricated from 1mm sheet steel, which you can see at the top of this picture. I intend to fabricate the lower outer sill but it’s made more difficult by not being a straight section. It tapers slightly towards the ends just to make things harder than they were already!

The next

thing is to replace on this side of the car is the rear spring hanger box, yet

another common failure of the Jag. The car has leaf spring suspension,

but instead of the traditional approach of being fixed at both ends with the

axle in the middle, the springs are inverted, fixed at front end, cantilevered

in the middle and attached to the axle at the rear end. An unconventional

approach!

I had to purchase the new spring hanger boxes as replacement parts. They

were pricey, but there was no way I could have made them as they’re very

substantial and as you can see, it was impractical to patch up the old

ones. I will need to take care with this repair, as the positioning of

the hangers needs to be exact. Any discrepancy will result in the springs

being out of alignment and the axle may not fit correctly or run

true.

Before the

hanger could be fitted, the floor above it needed to be repaired. As the

hangers share the same location as the problematic rear jacking point, it was

inevitable that the shell would be rotten here. The repair involved

stitching together multiple sections, each fabricated and welded into position

to replace the rotten metalwork.

I always try to retain as much solid metal as possible, so only cut out the

minimum required. This inevitably results in some odd shapes, this is

just one of the pieces required above the hanger/jacking point.

I’m not very experienced at anything more than simple fabrication, and just the

one section you can see below (which is curved in all three dimensions) took

quite some time. However it was immensely satisfying when I was able to

complete it. Working with steel is, unsurprisingly, far more difficult

than when creating a CAD template (Cardboard Assisted Design) to fit into a removed

section. When this ordeal was finally over, I was able to attach the new

suspension spring hanger box.

Here you can see that I’ve started to construct a replacement front jacking

point. The base of it, which spans across the new floor section is in,

but I’m unsure whether to weld on a box section receptacle in order to retain

the original specification (which I’m unlikely to use as I have no intention of

using a 1960’s jack), or to replace with a modern stub for my trolley jack to

locate onto. I will give that some further consideration before

committing to metal. I’ve also welded patches on the front of the floor into

the wheel arch area. There are plenty more of these patches to be

completed around the rest of the car.

The rear spring hanger is now fitted on the O/S and sprayed with galvanising paint. All welded and (hopefully!) in exactly the correct position. Quite pleased that my welding is improving, if not yet perfect. Not shown is that the Panhard rod eye has also been welded in, more pictures soon.

I started to clean the remainder of the underside and was very pleased indeed

to discover that the N/S chassis rail is quite solid. A hammer test had

it ringing throughout the whole length, not a single dull thud which would have

indicated that this chassis rail too had succumbed to the rot! So, some

great news, it will save me a whole load of time and effort by not having to

replace it. The front N/S jacking point can be seen here, which obviously

WILL need replacing. I was already aware that it had rusted away and

taken some of the passenger floor with it, but at least I’ll be tackling the

job with the experience of having already done the same on the O/S.

Despite being solid, the chassis rail has two places that require a small patch, one adjacent to the front jacking point (no surprise there!) and the other to replace an area with some tiny perforations close to the rear spring hanger (below).

Talking of the N/S hanger, I’ve had a quick look it appears to be in good

condition, but I’m unsure if it’s in ‘good enough’ condition. It

has a little corrosion on the side of the upper box, but I’m unable to see the

condition of the lower box until I remove the leaf spring. I’ve no plans

to do that just yet until I’ve completed the O/S, just in case I need to take

measurements to cross reference.

So, another day, another fabrication and another weld….

The

O/S inner sill was pretty much sound, so given that you need to cut the old one

away from all three door pillars to replace (which is a PITA job), I decided to

patch up the old one. All of the lower section needed to be replaced,

which is quite a simple fabrication. The upper section only needed this

little bit to be replaced, which is also not too difficult a job, and I quite

enjoyed doing it. Here it is ready for primer and then to be welded in.

And here’s where it fits on the car. This just leaves the small section of

lower sill to be added between the front and rear replacement sections.

Once this was welded in securely, I was able to then fit the rear jacking

point. I was hoping to fabricate one as I did for the front to save

further spending, but given the complex shape and that it’s made from much

thicker 2mm steel, I decided to buy it.

The O/S is nearing completion, but before I can start on the rear of the car, I

need to do exactly the same now on the N/S. Here’s a comparison of the

jacking points as they currently stand, rears then the fronts. (The front O/S

hasn’t had the box section and wedge welded in place yet, but that’s on

tomorrow’s task list)

The inner sill is now complete, and the centre section of the outer sill has

been fabricated and welded in. New (and expensive) sills are available, but

as it’s mostly just the lower section that was rusted, I thought I’d make my

own. They’re trickier to make than they look, not only do they curve

towards the bottom, they’re also curved front to rear, tapering at each

end. They’re far too complex to make in one go, so I’ll split into (at

least) three sections which makes them a little bit more manageable. Before

butt welding the first section into place, I used panel sealer on the inner

sill to prevent any moisture creeping in, before a thick coat of paint.

You can see that I’ve not plug welded the underside where it attaches to the

inner sill just yet. This is in case things go badly wrong and I have to

end up buying readymade replacement sills, it would save cutting this section

back off the inner sill, causing a right mess. I’ll leave that job to

last when the sill is finally complete.

OK, the next outer sill section went quite well, so I bit the bullet and plug

welded the bottoms onto the inner sill. Quite pleased with the

result. Just the ends to do now. Front is complicated by the front

wing also joining onto it, and the rear has the wheel tub and spat to align and

connect with.

Today was supposed to be the day I started on the rear wheel spat and

arch. I have cut down the full sized spat, to be less than 1/5th

of its original width. This is to make a sportier look and one which was

adopted by the Coombes Jaguar Racing Team. This also helped with quick tyre

changes as the spat no longer needed to be removed first. Anyhow, before

I was able to start on the spat/arch, I checked the wheel tub only to find some

more rust which needed to be removed. A simple repair, but it took me

long enough to delay the planned work. So guess what tomorrows job will be!

The rear end of the sill and the inner wheel arch section was completed and

finally boxed in. Deciding to go for the sportier narrow spat, mine was a

cut down from a full sized original. I used a length of electrical

conduit to create the wheel arch which I formed around a wooden template.

It proved to be very difficult to shape exactly, but I got there in the

end.

The front wing was badly corroded along the line of inner baffle panel.

There were two areas which I decided to tackle separately because the

last thing I wanted was for the wing to become mis-shapen

due to lack of strength. Both patches were butt welded in.

It’s

shocking to see how much filler was used on the previous repair. As you

can see, my repairs were fabricated from sheet steel but the remaining part for

the front wing which completes the arch and the front sill area will be a factory

repair section.

The reason that the wing had rusted out where it did, is because directly

behind it is a baffle panel which prevents road dirt and moisture getting

caught up in the corners of the wing and door A

posts. The problem is that it collects in front of the baffle

instead. This had inevitably rusted on my car, spreading to the wings.

There was a previous repair, but it was performed very badly, but it did

continue to do its job of keeping the area behind it clean which was some good

news at least. Now that the wing has been (partially) repaired, I needed

to fabricate a new baffle, but first I wire brushed, rust treated, primered and

painted the area behind to prevent any future issues. I’ll fabricate the

baffle in two sections for a couple of reasons. Firstly, I don’t yet have

the wing/sill repair panel which the lower section of baffle needs to attach

to, and secondly (and possibly the more important reason) is that it’s far

easier. The lower section is complex enough without the additional

overhead of doing the upper section on the same piece. They’ll be fully

welded and also out of sight, so it will make little difference. Here’s

the area behind the baffle, and also the upper section tacked into place.

I will fully weld when I have all of the components to complete the job.

So the repair panel has arrived. It’s expensive, but unfortunately so much of the old panel had rusted, I have no idea of its shape and position to make a panel myself.

Now that I have the panel, and given that I’ll only need to use about 20% of

it, I may try to fabricate one and then sell this one on eBay. I’ll have

a go, and if it turns out to be unusable, then I can always use the new one.

Now that I have the position of the wing/arch, I can start on the baffle

section number 2. First I need to make a box to finish the inner section

as the old one rusted. I have no idea what it’s called, or what it does

really. It’s simply a box inside the forward sill area. But, it was

rotten, so I made a new one.

Once that was completed, painted and then sealed, I started on the lower

baffle. A cardboard template was used (well, actually 2 or 3 of them, I

lost count in the end) to get the correct profile of the tub, but this is far

easier than committing to steel too early. I used tabs which will fix to

the inside of the wing, they can bend a little either way, so this will give me

a little bit of flexibility in case I need to fettle the wing when fitting, but

the tub side was fully welded, along with the top section. I also had to

fill weld a few perforations which is why there are some ‘extra’ areas of

welding. Just in case you were wondering, which you probably weren’t.

So, the baffle is now complete and ready for the final part of the jigsaw to be

fitted. As I said, I will attempt to use what remains of the rear spat

arch, to make this panel, but it’s a 50/50 chance it will be of any use. (more like 100 to 1!). I’ll give it a go tomorrow.

OK, so it didn’t work out. I didn’t even attempt it. I sat for an hour

looking to see how I could do it, but with a different radius to the arch, a

change in profile required and also the arch lip needing to be extended, I

thought it would be best to just use the new panel. So, here it is, ready

to be welded in. I ran out of time to weld today as we were too busy fitting

wheel arches to the Mini, but hopefully tomorrow.

It was a nice evening, so I took some of the woodwork home to start the

restoration of that. Nice to have a bit of a change from metalwork all of

the time. I started to remove the varnish from the walnut veneer

passenger dash face. It’s so delicate and brittle, this stuff is over 55

years old, but I took it slowly and it went OK, however there’s lots of flaking

in other surrounding areas. I’ll need to re-veneer those parts I think,

they’re too far gone.

The section of the wing/arch/sill was easy enough to weld into place, taking

care not to overheat the panel and cause it to warp. I was a little

disappointed that the sill didn’t quite reach the new panel, but it was

something I didn’t even consider when I was making that section, and it’s easy

enough to make a filler piece. I’ll learn from that when I’m doing

the passenger side.

The baffle fits into the arch well and I’m pleased that I saved £200 on that

panel alone. But more than the financial saving, it’s very satisfying

when you are able to fabricate something from scratch. It needs attaching

to the new arch, but I’ll do that when the car is flipped over, so I’m not

welding upside-down.

Patched up that gap in the sill today (the image below is before the welding

was complete, it just shows the tack welds holding it in place), not a big job

but as the sill is now finally complete, I was able to assemble some more of

the front jacking point. It’s a substantial piece made from a 2mm base,

3mm box section and a 3mm reinforcing top plate. I’ve not yet welded the

top plate on, but the rest is now on the car.

Not much to show for my efforts over the last two days. Scraping off

underseal down to the factory primer is no fun. I only managed to finish off

the O/S rear wheel tub and the boot tunnel, but my arms are aching now.

Fortunately the shell is in good shape under there. Just one 10mm hole to

weld at the joint. The shock absorber mounts are nice and strong, look as

good as new too, so I’m pleased with that.

More scraping, more underseal removed, from the spare wheel well today.

Some small rust holes that will need attention, but solid enough.

Time for some more woodwork. The main instrument cluster for the speedo

and rev counter was ok, but not really the best, so I decided to re-laminate

it. The wood used for almost all of the interior is burled walnut. I

bought 5 sheets where the grain pattern was very similar. They arrived quite

wrinkly, so needed soaking and pressing for a couple of days first. They

were then dried out and glued to the binnacle, book-matching the pattern as

best as I could. I made the centreline between the dials, rather than the

true centre of the piece as this is where the steering wheel will also centre

and it looks more natural. The first coat of varnish really brought out

the grain, but needs many more coats before it will be as flat and as I

want. I also had to replace the sides of both dash panels. These

were smaller and far easier.

Took her out for a spin today, quite literally! I’ve pretty much completed the

O/S of the underneath, so I turned the car around in the garage to work on the

other side. The rotisserie does rotate in both directions, but turning the car

around means that the N/S will be uppermost and facing the workbench/tools

instead of a wall.

As I mentioned before, I did hope to be able to refurbish the N/S rear spring

hanger, but upon closer inspection it really was too far gone. So, off it

comes. Before removing it, I made a bracket to ensure that it’s replaced

in exactly the same place. It’s difficult to remove the old hanger

without damaging the body shell its spot welded to. But, I took my time and

managed to remove most of it tonight, and was really pleased that the floor was

in far better shape than the O/S. I may need to make a very small patch,

but that’s going to be a flat piece, so should be really easy. What a

contrast to the last one. I’ve ordered the new spring hanger which should

be here in a day or two.

So the spring hanger sections arrived, and after making a small repair to the

floor, I’ve welded in the upper section. Unfortunately, however, the

lower section isn’t a great fit. I bought them from a different supplier

than normal because they were almost £100 cheaper. But I suppose there’s

a reason it was cheaper. I’ve queried with them and will return just the

lower part and buy a better version. Anyhow, you can see the bracket I made to

ensure the correct positioning of the replacement hanger, any misalignment

would result in the rear axle not fitting squarely. The original hanger is spot

welded on, but instead I’ve drilled 9 small holes and will plug weld from

inside the car, along with welding to the chassis rail, rear inner arch and

numerous other places. This needs to be a robust fixing, as the back axle

attaches to these via the leaf-springs. Also visible are the repairs I

made to the spare wheel well.

I welded in a small repair where the join had rusted adjacent to the new hanger, obviously cutting out all of the rust and fitting the patch into the hole rather than simply welding over the rusty bit to prevent any future corrosion. I fill welded the small holes, just above it too. Welds underneath the car don’t need to look pretty, so I rarely grind them off because it also weakens them slightly. On the left is the inner sill, the bottom half of which needs to be completely replaced.

Choosing not to replace the N/S chassis rail saved a whole load of work, but it

did need two repairs. The first one was where the front jacking point

attaches to it and also the floor above. All of this had rusted and what

appeared to be a small rust hole in the chassis was actually a big rust hole in

the chassis. The floor needed a big section cut out too but I already knew

about this and have a repair panel in readiness. Obviously I needed to

make a sound repair to the chassis, and I cut out a large section to ensure

every bit of rust was removed. The chassis is made from 2mm steel, so

double the thickness of body panels, which is both a blessing and a

curse. It’s easier to weld because it doesn’t blow though so easily, but

it’s far harder to work with and also I don’t have a sheet steel brake/bender,

so the fabrication of the repair sections takes a lot more effort.

Whilst there was a gaping hole, I took this opportunity to remove any debris inside

and to treat any surface rust with ‘rust converter’ to prevent any further

problems. I did grind these welds down because I need a flat surface to

weld on a new jacking point. Next thing to tackle is the floor.

The 3mm sheet

also arrived this weekend, so I was able to complete the O/S Front jacking

point. I needed to make and weld on the triangular piece to complete it, but it

took one and a half cutting disks just to cut this out. Glad there’s not

too much metal this thick on the car. With a bit of luck, soon the N/S

will also look like this.

Well, not too much to report over the last couple of weeks. I’ve managed

to make some progress, but it’s probably a bit boring because it’s simply a

repeat of the work carried out on the other side. The wheel tub needed a

small repair, well, actually it needs two repairs. I did the small one on

the join, but the rear area also needs to be replaced, but that will be done

when I start on the rear valance and tonneau panels.

The lower spring hanger box replacement arrived and was fitted into the upper

section. Not an ideal fit as the two parts were from different

suppliers/manufacturers, but after some fettling I was able to weld it in

accurately. Actually, the welding was the hardest part for this section

because Halfords own brand ‘Weld-Through Primer’ is definitely NOT what it

‘says on the tin’. I will not be buying that rubbish again. The

inner sill section was also fabricated and welded in, along with a section of

the outer sill. Below you can see all of that and also the rear jacking point

(currently resting in place prior to welding) testing the fit. The sill

inside edge is a bit hacked, but this will be trued when the sill is complete

and I can run the grinder down it in one go.

Really not had a chance to work on my car for ages as the boys cars have been

taking priority. Callum’s Mini has been completed now and passed its MOT

first time with no advisories. But as soon as that moved out of the

garage, Harrison’s MX5 has moved into its place. It needs plenty of work too, and

last night we started by removing the O/S rear sill and most of the inner wheel

tub. Hmmm, Déjà vu!

Anyhow, I did

manage to weld on the last section of inner sill on mine, I just need to buy an

arch/sill panel like I did on the O/S, and make the baffle panel to finish it.

Also completed welding in the N/S floor repair section, so the floor of the car

is now complete which is a major milestone. I’m

desperate to carry on, but I just have no time lately.

I thought I'd

post a quick update as this Sunday (being Fathers Day)

nobody could deny me the pleasure of working on my car! I’ve started on the

rear of the wheel tub/valance/tonneau panel area. The lower tonneau panel and

valance was almost completely missing, so it was very difficult making

replacements as I had nothing to compare the shape to. Despite looking quite

unassuming, this was by far the most complex panel I’ve fabricated so far, and

took two attempts. But after looking online at other cars, and doing some

research, I managed to get something cobbled together in the end. There

is a cut-out required in the valence for the exhaust exit, but I’ll deal with

this later. The box section was quite flimsy before being welded in, and

I didn’t want to work on it whilst in this vulnerable state. I just hope

I don’t mess it up after all this hard work. I also ran out of MIG gas which

didn’t help, so I didn't quite finish what I wanted to. My usual supplier has

none (covid-19 issue) so I bought a 900ml can from Halfords. Well, that didn't

even last the day! Will try further afield for a full size bottle this week.

I've not done a great deal lately I'm afraid. For me at least, things are

really busy at home and work, so I've just not had the time. Having to continue

to work from home (as usual) during lockdown, with a family that have been

moping about, complaining that they are bored and have nothing to do, is

frustrating in the extreme! I would love to have their free time, the car would

be half-finished! I did manage to get the homemade rear wheel arch/spat fitted

in over the weekend though. I do like the cut-down spat, and is a halfway-house

between the full original spat and the (effectively) spat-less solution

utilised by the Coombes teams. I believe they used a copper pipe brazed into

place on the original empty arch. I just cut down the spat and welded on a

piece of steel conduit as I've no brazing experience or equipment. If you have

any intention of doing this....don't. Unless you've access to pipe bending

equipment. It was a PITA. The conduit was so difficult to shape and I'd have

used an alternative method to achieve this had I known then, what I know

now. I was put off buying the new panels for these from Robeys, as they’re over £200 each, so perhaps it was the

right decision, I don’t know. Anyhow, it's almost complete now, just some

tidying up at the end of the sill.

Whilst I've been too busy to get over the garage, I've not been too busy to spend some money. I've recently acquired a set of wire wheels, a couple of splined hubs, a front wing/arch/sill repair panel, rear bumper, as well as some other bits and bobs that will come in handy later on in the build, if I can remember where I put them!

So with the holidays cancelled due to Covid, the time

I’d planned to be in Spain has been used to make some progress on the

car. The front of the arch where it joins the sill has been completed….

…along with some other tidying up of uncompleted work.

The front chassis where the subframe mounts had a small rusty hole, which I

picked at until it needed a whole new patch. It looked like nothing and I

almost didn’t bother, but I’m so glad I did. Wouldn’t want that to bite

me later on. The plate was 2mm steel and needs the tube to stop the chassis

leg deforming when tightened down.

Last big panel to fit was the N/S arch/sill. I debated about using a

joggler and then ‘overlap welding’, but I decided to ‘go with what you know’

and butt welded it the same as the other side. I set it using some ‘butt

clamps’ and really took my time, making sure I cooled the area with a damp rag

to prevent the heat building up and warping the wing.

In my haste to fit the arch, I omitted to put in the baffle panel first.

Actually I did think about it, but thought I would be able to easily fit it

later. Wrong! It wasn’t easy at all, and needed to be made in three

parts rather than the two I used on the other side due to the restricted

access. Here’s the first two pieces in place.

Fitting the arch panel meant that the sill could finally be completed. I

forgot to use the punch to make the holes for the plug welds onto the inner

sills, so needed to drill them instead after this photo was taken. The

square marked needed to be replaced but when the car was made in the factory,

lead was used to fill the panel gaps, which make it a little ‘exciting’ when

welding near it. It melts really fast and splatters everywhere, but I

think I managed to remove most of it now. After fitting the front sill section,

I had to adjust and re-weld the existing central part of the sill to align

correctly. Something had obviously been measured or fabricated

incorrectly, but luckily I was able to correct it when it all came together.

I’d removed 95% of the underseal from the underneath of car, and only a section

above the petrol tank remained. I was confident that because it’s well

protected there and looked in really good shape, that

the metal under it would also be in good shape. Not sure what made me

start to poke about, but as soon as I started to remove the underseal, I could

see that the rust had got under there too. Some small ‘scoops’ were

fabricated over a wooden former to replace the ends of the pressed sheet, and

then welded in. So, that’s all the under seal removed from the underneath

now, just the wings to do.

It’s sometimes only when you step back and take stock, that you realise how

much you’ve actually accomplished. When I took these two photo’s I

was pleased to see how good the underside is looking compared to last

year. I have the O/S valance area to do and that’s pretty much it for the

big jobs underneath. But still plenty to do with running brake &

petrol pipes, cleaning and fitting the exhaust shields and undersealing.

Also need to revisit the front part of the chassis and crossmember. It

seems so long ago I completed those, and my experience with fabrication and

welding has improved a great deal in that time, so I think there may be some

areas I’ll revisit to make sure are still good enough now. But at least I

feel as though I’m on the finishing straight!

So just the aforementioned rear valance area. It’s not in a good shape, and

I even had to remove a good section, to be able to access the bad section

underneath. I could have just sprayed some rust treatment up onto it as

it’s not a structural part. And being hidden out of view, nobody would

have ever seen it, but I know it would play on my mind if I’d left it.

Today I managed to complete the valance end on the O/S. I made it

differently from the N/S and I think on reflection it was a better

result. It’s only a small update and the piece in itself is

un-spectacular, however it is significant. Whilst the panel was not an

easy one to make, it does mark the end to the underside welding, so it is

notable and a marked milestone on the cars restoration. I still have lots

to do of course, but the major reconstruction work of the underside has finally

had a line drawn underneath it.

Today I finished some tidying up and coated the underneath with underseal. I opted for Upol Gravitex for a few reasons, firstly it’s half the cost of Upol Raptor, and secondly it doesn’t set as solidly as

Raptor. I’ve heard that Raptor is so

hard, that sometimes rust can develop underneath it, but the strength allows

the coating to remain, suggesting that all is well. That is until the rust becomes so bad, at

which point it’s too late. So, anyway,

as this is cheaper too, it’ll do for me.

It’s applied with a Schutz style gun, which gives a pleasant ‘orange

peel’ textured surface. It’s also matt,

so I will give a brushed coating of gloss paint so that it can be cleaned more

easily. It went on quite well, but 6 bottles didn’t go far, and I didn’t end up

finishing the front chassis rails.