Wiring

The existing

loom was a real mess, with some of the cloth sleeved wires cracked and flaking

off, lots hacked and butchered by a previous owner and almost all of them under

the bonnet joined…badly. A new loom would cost in the region of £400 but

wouldn’t be suitable anyway because I intend to make some important

upgrades. The original loom had a grand

total of two fuses which is clearly not suitable for a modern restoration. Also

I’ll be replacing the dynamo and voltage regulator with a modern alternator,

changing the amps gauge for a volts gauge as the old one cannot handle the

alternator output current, adding a Hi-Fi system and amplifiers to match the

one in my newer Jag, adding a reversing light and relocating the battery in the

boot. So clearly a ‘stock replacement’

wouldn’t be worth buying. I’m no

stranger to car electrics, well, at least the rudimentary wiring fitted in my

early vehicles, so I intend to make my own wiring loom. It looks to most people to be a complicated

minefield, but when you break it down, it’s simple enough if you take it one

circuit at a time. If you want the

lights to work, you don’t need to wire the whole car, you just need to wire the

lights. Do that a dozen more times for

the other components and you’re done.

I’ll be

fitting a modern fuse box and relay box so the system will be much safer. The cost of the wires however is always a

stumbling point for bespoke looms, it’s not cheap as you need to have many

different colours and a few different gauges. A better option is to buy a loom

from a donor vehicle and strip it for the components. I managed to get one from ebay

from a high end Mercedes, so this obviously had all of the additional wiring

for the extra features so was perfect.

I spent a few

hours stripping it down, and now I need to organise and categorise each one.

Update December 2022

So, the loom

above, when stripped down, didn’t actually yield as many usable wires as I’d

anticipated. Bum! So, after some further searching, I managed

to find a complete loom from an Audi Q series car that was being stripped due

to a cambelt snapping and toasting the engine. It was reasonably cheap and reasonably

close. Well, close enough to collect it

and also take the wife on a jolly, still getting back home in the same day!

The last loom

was a massive job to strip and organise the wires, and now I had another even

bigger one to do. It took me a day or

so, and this time I labelled the length of each piece too, which was something

I only thought of after I completed the first one. Never mind, better half labelled than

none. Almost done here -

I think that

I now have sufficient wire to complete the loom, plenty in fact, and I still

have some bits that I haven’t stripped yet.

I did the easy/best bits first.

As the original fusebox was about the size of a

matchbox under the bonnet, trying to find a space for a more substantial unit

to house the additional fuses and relays was a bit of a conundrum. In the end I copied someone else’s idea

had a brainwave and decided that, as there was no room under the bonnet, the

next best thing was under the passenger dash area. A hinged panel will drop

down to give easy access to the fuses and relays, but can then be screwed back

up to be both discrete and secure. This

is also a busy area with the wiring loom, so an ideal place to tap into the

circuits without too much redirection.

I had a large

piece of aluminium which will serve as a base.

After far too many fitting attempts, I was eventually happy enough with

the size and shape and committed the card template to the sheet. There was a

slight cutout for the heater vent and a bend of about

30 degrees at the midpoint. I managed to perform the bend without too much

drama because the aluminium is reasonably soft.

But I really need to take some time to make a metal sheet brake (metal

bender) which will make life so much easier.

Anyhow, I have two banks of fuses, the larger will be for switched

supplies, and the other smaller unit for permanent or unswitched

supplies. With a total of eighteen fuse

slots available, I’ll be able to vastly improve the safety of the

electrics. There are also six relays, in

two banks of three, which will supply the high power items such as high beam, fograngers, horn, etc.

To make the interface more user friendly, I also have a bank of twenty

connector strips.

Being old-school, my first instinct was to plan to solder all of the electrical

connectors. The last thing I want is to

have any issues due to poor connectivity.

But after a fair bit of research and consulting with The Google, I had

my mind changed when I discovered the more modern crimping tools that are now

available to the home user, especially as they are very reasonably priced. Just had to wait a week for a suitable device

to be delivered from China. They are

available from more local suppliers, but they are exactly the same item, just

twice the price. Being in no particular

rush, and also being particularly tight, the wait was insignificant.

Before fully

committing to this new fandangled device though, I

first performed a few ‘test crimps’ to make sure that they were of sufficient

quality for both the electrical connectivity and the mechanical integrity of

joint. I was more than pleased with the

tests, so it’s full steam ahead with the crimping. (Despite some part of me still wanting to run

a slither of solder over them ‘just to be sure’, I think that I will try my

best to resist and put my trust in these.

Old habits and all that.)

Update - What happened in

January then?

I’ve been

busy over the last month, so not a great deal has happened really. "What, again??" I hear you

shout. Yes again, I'm afraid. Firstly

Christmas, and then five cars to get through their MOT's, each requiring a few

minor bits and bobs to sort out, which they inevitably discover on these

tests. Also got a little distracted

with my new toy (more later).

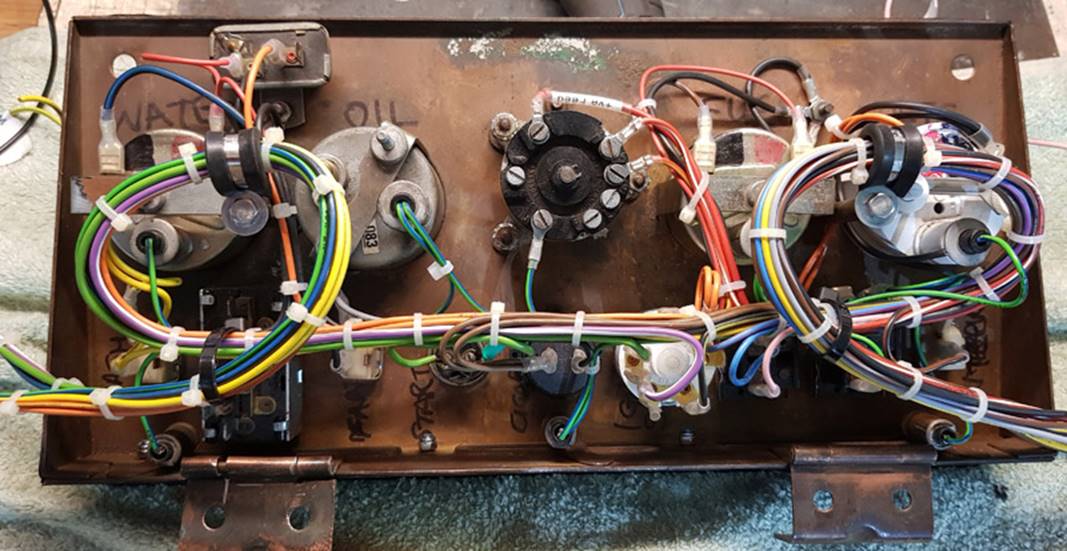

The main

fuse/relay board has been wired completely apart from the 40amp wiring which

I'm waiting for terminations for. I should have enough fused circuits now to

make for a safer wiring loom, and relays for all of the high power, high

current items. I’m quite happy with it,

although if I did this again, I think I could have made it slightly

neater. Regardless, it'll be tucked away

under the passenger dash, so not the end of the world.

The original

battery location under the bonnet has been taken over by the upgraded dual

circuit brake servo and master cylinder, so I now have to find a new home for

that. The traditional place is in the

boot, so that's what I will do. I knew I

needed to relocate the battery early on in the build, so when I did the underside,

I pre-installed rivnuts all the way down the nearside chassis rail for the

cable to run along, so that will save a job under the car. It's all well and good fitting the battery in

the boot, but there obviously isn't a way to attach it there. So the next job then is to build a battery

tray and find a method of retaining it.

I made a basic battery tray from four bits of angle iron welded

together.

Then I needed

a way to securely hold the battery in the tray.

I had considered two lengths of threaded rod with a retaining bar over

the top. This was a popular method back

in the day, but this does, to my mind at least, look a little industrial. Modern designs use lower brackets to clamp

down on the stepped bottom edge of the battery and is far neater. This is what I went with and they turned out

quite well, despite taking much longer than their simplistic design would

suggest. The top piece has an elongated

hole to allow the movement required to adjust and this is located over a

captive bolt which I welded onto the tray.

That's as far

as I got before it all came to a halt for me to play with my new toy.

I'd wanted a

blasting cabinet for a long time, so when a friend of mine said he was getting

rid of his, I jumped at the opportunity.

Really, I bought this three years later than when I needed it the most,

and should have bought one when I was doing the body and running gear. But, I

have it now. I gave it a try with a

spare inlet manifold I had in the garage, and after making some tweaks, I was pleased

with the results. It came with a load of glass beads media, which is good and

gentle for alloy components, but I've ordered some aluminium oxide media that

will be a little more aggressive.

February 2023 Update

So, what did

I do in February? I know, I know. It's

mid-March now. I bet you guys have been

on tenterhooks waiting for the next update yeah. Yeah? No?

Oh, OK. Well, here it is anyway.

More

wiring. Firstly, because I decided to

upgrade the fuseboard etc,

I needed to have a wiring diagram to follow.

Obviously none exist for my particular circumstances, so the first thing

was to draw up a completely new wiring diagram.

I used the original one as a template to work from, and then added the

bits I upgraded, and removed the things that were no longer required. It's

still 'work in progress' so please don't consider it as the final draft, and

heaven forbid, please don't copy or use any of it. I hold absolutely no responsibility if you

copy it and your car catches fire!!

There are a few things that I still need to sort out, but it's 90%

complete. The wipers are one of the

things left to do. Because I've not

decided on the final position of the motor, I may well use a different motor

model. So no point in working out the

wiring just yet, as the requirements may differ.

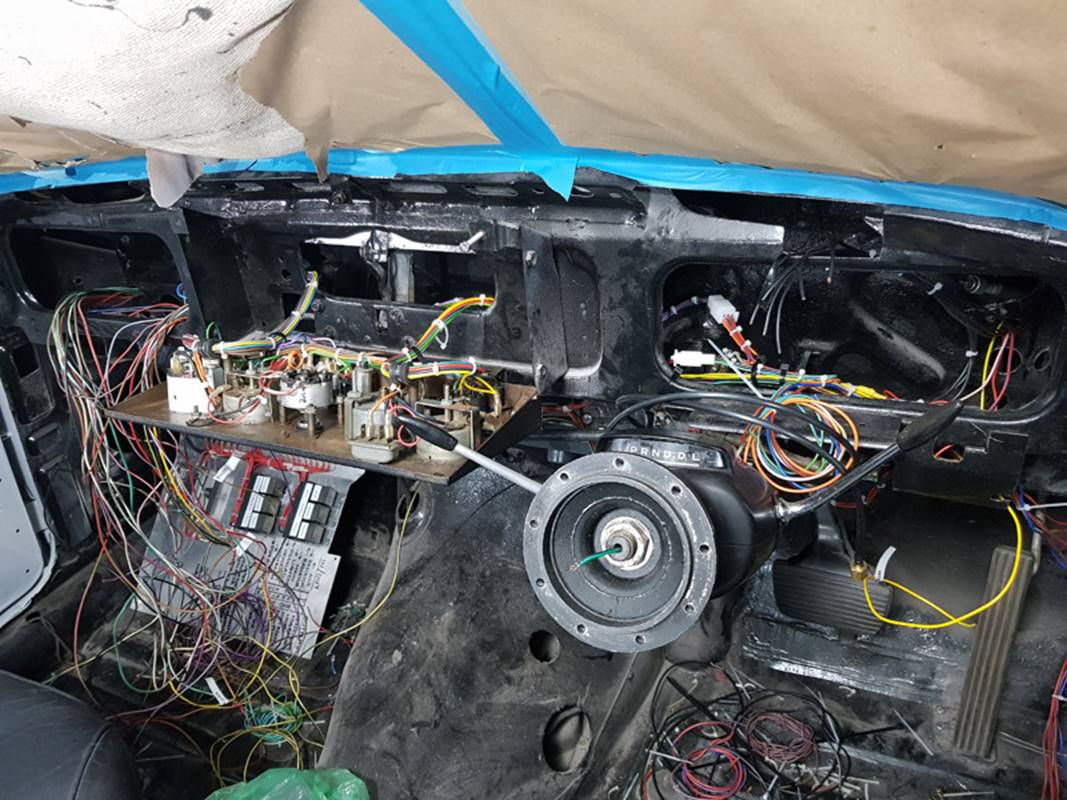

So, now

running the wires. Firstly I decided to tackle the centre dashboard. This is where a lot of the wiring culminates,

and it's a bit of a rats nest. It's

difficult to try and keep things looking tidy, especially when you don't have a

definitive plan. It has helped

enormously however, that because I'm now using relays for all of the high

current components, many of the wires can be a lot smaller diameter as the

current draw of a relay is significantly less. This means they take up less

room and are more flexible to route. So

here is how it looked before fitting, and again once the dash panel was popped

back into the car.

Fuseboard aside, the second biggest

accumulation of connections is around the steering column stalks and main dash

area. The auto gearbox has a mechanical

lever to operate, with little electrical connectivity other than a backlight

for the gear position indicator, so that was straightforward enough. Next was something I'd been dreading. My original indicator stalk was long past it's best with the main plastic component broken, it was

never going to work again. A complete

new replacement, if you can find one, is in the order of £250 for anything

decent. £100 for something that was only

marginally better than what I already have.

So, after much deliberation, I decided to ditch the whole thing and buy

a modern equivalent. The closest one I

could find, and the one I ended up with was a direct replacement for an

MGB. I needed to increase the diameter

of the column clamp and used an offcut of stainless bar as a template for

this. Then I cut off the indicator stalk

and fitted the old one from my redundant switch-set. It's all working well and overall I'm pleased

with the result, but the quality of the replacement part isn't up to the

standard of the original. It was only

£30, so I shouldn't have raised my hopes too high. The indicator action isn't really that

positive, so I may re-visit this again as a winter project on day.

I then

refitted the cowl which surrounds all of the switchgear on the column. These parts are obviously old, and were made

from a material that was fragile even when new.

I guess you know where I'm going with this. Yes, I slightly

overtightened one of the screws and one of the three mounting points gave

way. I don't recall if there were

originally rubber bushes on these or not, but I think going forward, there will

be for sure. I don't want a repeat of this.

So, after a bit of 'JB Weld' and an overnight wait, I'm back on

track. All fitted on and after a slight

trim of the aperture to accommodate the marginally different position of the

new stalk, I'm done.

Next up, the

front half of the car. I ran the wiring

for all of the front lights, the horns, thermostat sender, etc... I've decided

that I will be ditching the mechanical, engine powered fan in favour for a

modern electric equivalent, so the wiring for this was also installed. Another

modern upgrade I decided to fit is a central locking system. These are not expensive from your favourite

online auction site, and after a few weeks for it to wing it's way from China (where else!), it was laid out on

my garage floor for testing. All worked

fine, so I now have the additional wiring for this to include along with the

rest. Some of the bullet connectors look a little bit suspect, so I'll be

replacing those with some solid soldered joints once the lengths have been

confirmed.

The car was

originally fitted with a dynamo and all of the accompanying paraphernalia which

that it required. I decided to use a

modern alternator with an in-built regulator, and this literally needs three

wires. What a difference. Some of the

later cars were fitted with an alternator and they had a different alloy

bracket from the steel one I had. I

sourced one and had at last, an excuse to try out my newly acquired blasting

cabinet. It came out quite well, but I

may well powder coat it for an even better result. My son has bought all of the equipment and

has mastered the technique, so that will be done soon. One thing it needs however, is a small spacer

to make up the gap for the differences in the alternator designs.

So, that

leads me to my next disclosure. I bought

a lathe! It's something I've been wanting for a long, long time, and this

humble spacer was the justification I was waiting (praying?) for. Anyhow, here it is. It's a Clarke CL430 which is in great

condition. It's larger than a desktop model, but clearly not as big as a full

sized lathe. It will be perfect for the

jobs I intend to do on it, I just need some tuition to prevent me causing

damage to the work, the lathe or me!

Fortunately my dad has 40+ years’ experience as a machinist, so I'd best

get the teabags and biscuits ready.

Update - End of March 2023

Having had a look

over my new lathe, I attempted to make the spacer that I needed for the

alternator (above, remember?). It was a

first attempt but it did actually fit, although the surface finish wasn’t the

best. I found out afterwards that the

steel was not the best quality (You didn’t even know steel came in different

qualities? No? Me neither!) and also I used a steel, slightly blunt tool. Since this, I’ve had much better results with

tungsten carbide inserts. So here it

is.

I'd spent

ages wiring up my fuseboard/relayboard

and had never tested it. It's not like it's rocket surgery, just simple discrete circuits, but

there's always a chance that I'd made an error.

So I was really pleased when I tested it out with a battery and a couple

of fly-leads. All of the relays operated correctly, some requiring a positive

supply to switch, and others like the horn and engine fan needing a switched

earth to work. But all were fine along

with all of the fused circuits. It's a

nice feature on the fuseblocks I bought actually, there's an LED adjacent to

each fuse, and if a fuse blows, then the LED illuminates for easy

identification. I have fuses for most

accessories, so if for example the high-beam stops working, then the first

thing I'd look at is the fuse for the high-beam, and they're clearly

marked. But still, it does make

identification simpler I suppose. I

postponed fitting the fuse/relay board for the time being as I need to test fit

the glove box (which it sits under) to ensure I get the placement right. So instead I started on the power cable from

the boot mounted battery to the starter solenoid under the bonnet.

As you know,

I'd already made the battery tray and so I set about fitting it to the boot

when I realised that if I bolted it down through the angle iron base, the bolts

would stick up and prevent the battery from sitting flush on the bottom of the

tray. I wouldn't call it a mistake, more

of an evolution in the design. To work

around this I drilled the holes smaller than planned and tapped a thread so

that I could screw in studs rather than use bolts. I then welded them in place as I didn't have

confidence that the limited thread length would be sufficient to hold

everything down securely enough. It

turned out quite well and I was glad that this oversight didn't cause too much

rework. After painting the hole edges to prevent future corrosion, I fitted the nyloc nuts from underneath and I was happy with the result.

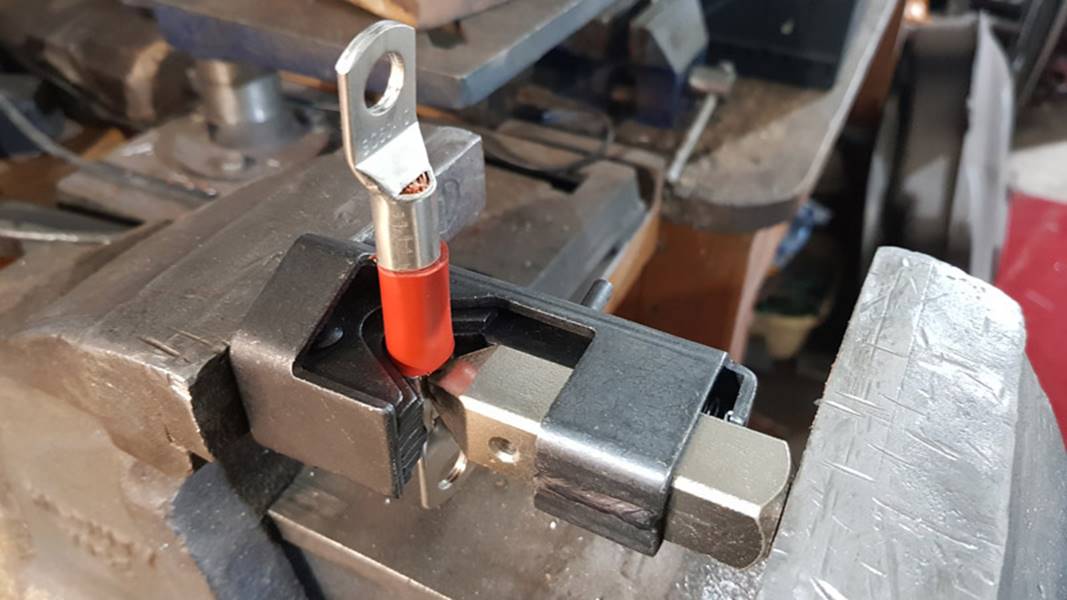

The cable was connected using large crimped terminals. The tool for this is quite a hefty piece of

kit, certainly compared to the one used for the normal wiring, and requires a

vice grip to make the connection.

The next

thing to consider was how to get the battery power out of the boot. I'd already decided to take a route under the

car, so I needed to exit via the boot floor.

I had considered a heavy duty grommet because I prefer the cable to have

as few joins as possible. It takes a

fair bit of current, so joint free is obviously the best option. However I'm wary that the cable can rub with

movement, and in time could potentially short out to the ground on the edges of

the hole. So rather than use a grommet,

I opted for a bulkhead terminal. It

safely passes the boot floor and has a secure connection either side. This decision

was compounded somewhat by experience.

Although not exactly the same scenario, I remember as a teenager when I

had a classic Mini and after going down a gravel track (I cannot confirm or

deny that it was 'at speed') a large stone kicked up and knocked the power

cable into a seam on the chassis, splitting the insulation. It shorted out, quickly followed by acrid

burning smell and some smoke! I was fortunate that no further damage was caused

to the car, probably due to the fact the battery was on it's last legs anyway, and this was just the excuse

it needed to give out altogether. Not

sure that my Dad knows to this day the reason for the jumpstart I needed 'out

of the blue' one night. No major drama,

but it did teach me a valuable lesson. Anyhow, here’s the bulkhead

fitting. Note, I did paint the edges

before fitting.

I'd always

thought a battery isolation switch would be a good idea as the car will be laid

up for the winter months. This will

ensure there's no chance of battery drain and of course an added bit of safety. I’ve not fully tightened the bulkhead nut yet

as I’m waiting for rubber boots to arrive so that the terminals will be fully

insulated.

I'd already

planned the route for the cable whilst the car was still on the rotisserie, and

all of the rivnuts had already been fitted in the nearside chassis leg in

readiness. I'd done this as I thought it

would make running the cable a bit easier.

How right I was! Had they not

been done earlier, there is no way I could have fitted them at this late stage.

The exhaust and heat shields would have made it impossible to drill them. But

they had been done and running the cable was a reasonably easy affair. The cable looks close to the exhaust in this

first photo, but it’s far enough away, also I removed two sections of the

heatshield to facilitate the cable fitting, and these need to be put back on.

So, the cable is now routed to the front of the car but I'm unsure of the best

way to reach the solenoid which lives at the very top of the bulkhead. More on this next month....................